A-01/A-08

General Knowledge and Inspection

The A-01 and A-08 show up when the Exhaust Fan Motor is not spinning at the designated RPM. The only difference between A-01 and A-08 is the moment when the error triggers; the A-01 shows up when the Exhaust Fan RPM is incorrect during preheating and roasting, while the A-08 only shows up during cooling.

The following table shows the approximate RPMs on each Fan Settings:

| V1 Exhaust Motor (RPM)(Black) | V2 Exhaust Motor (RPM)(Silver) | |||

|---|---|---|---|---|

| Chaff Collector | No Chaff Collector | Chaff Collector | No Chaff Collector | |

| F1 | 640 | 660 | 579 | 631 |

| F2 | 880 | 900 | 779 | 858 |

| F3 | 1,120 | 1,140 | 988 | 1,096 |

| F4 | 1,420 | 1,440 | 1,190 | 1,301 |

| F5 | 1,660 | 1,680 | 1,400 | 1,516 |

| F6 | 1,840 | 1,860 | 1,619 | 1,709 |

| F7 | 2,080 | 2,100 | 1,792 | 1,884 |

| F8 | 2,340 | 2,400 | 1,994 | 2,118 |

| F9 | 2,620 | 2,640 | 2,156 | 2,300 |

| Fa | 2,880 | 2,940 | 2,404 | 2,597 |

| Fb | 3,180 | 3,240 | 2,653 | 2,900 |

| Fc | 3,720 | 3,780 | 3,232 | 3,550 |

When the A-01 or A-08 shows up, follow the steps below to check the Exhaust Fan Motor:

- Check if the Exhaust Fan is running at the designated RPM.

- Check if the Exhaust Fan has stopped spinning or making noises.

- Review your ventilation setup.

Identifying The Issue

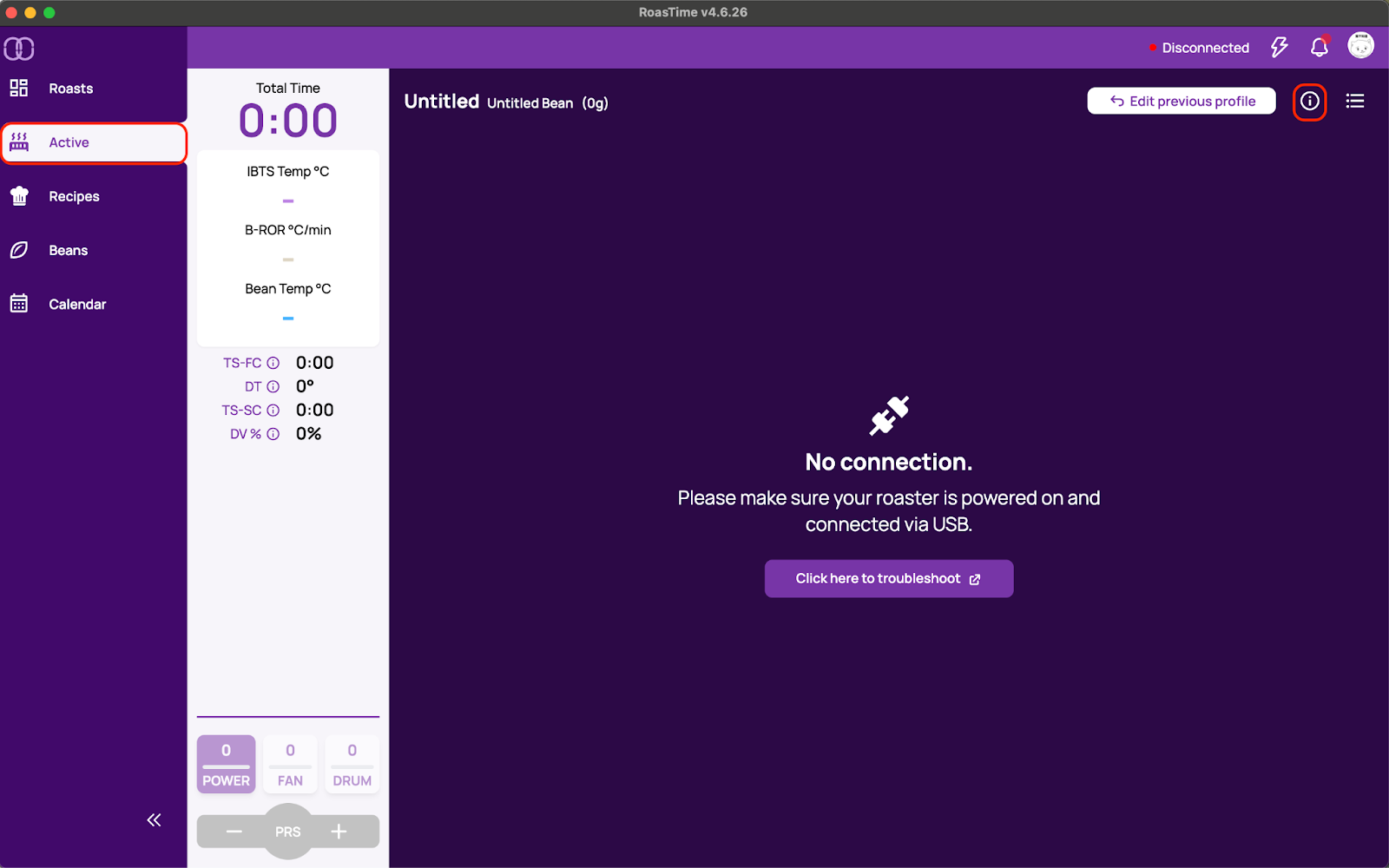

You can check the Exhaust Fan RPM through the Info Panel on RoasTime:

- Connect the Bullet to your RoasTime.

- Go to Active Roast and click the 'i' icon on the top left.

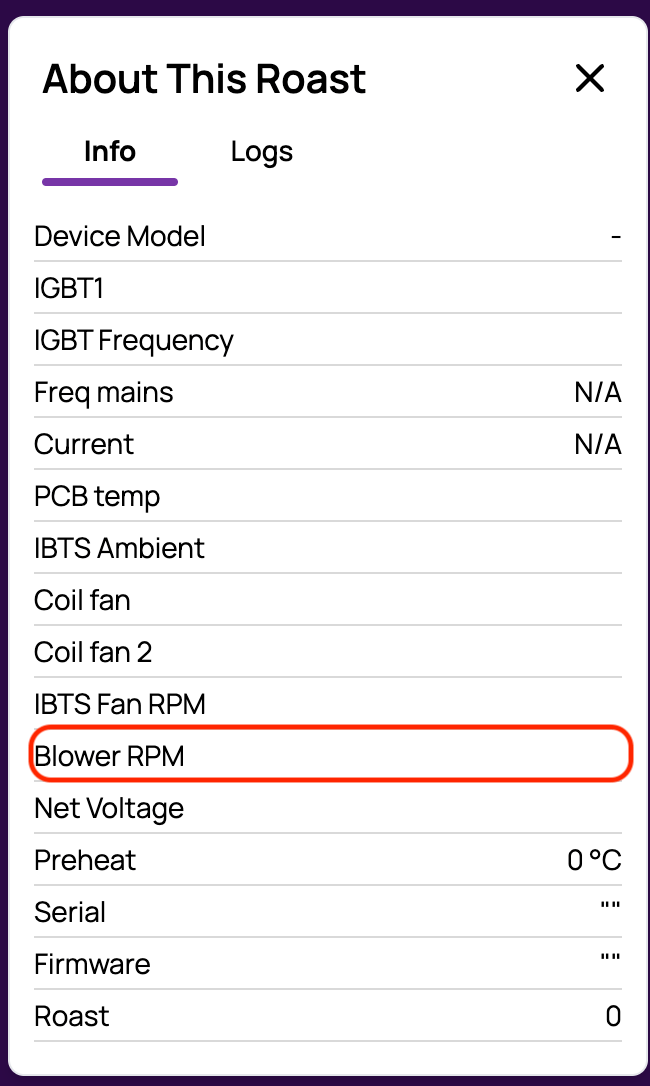

- Check the readings labeled 'Blower RPM'.

- Go through different Fan Settings and compare them to Table 1.

- Look for abnormalities during the test (i.e., Exhaust Fan Motor does not spin, Back Assembly making loud noises).

Miscalibrated Exhaust Fan RPM

If the Fan RPMs are off by at least 100 RPM, the Exhaust Fan Motor is miscalibrated. Follow the Fan Calibration Guide to recalibrate the Exhaust Fan Motor.

- Exhaust Fan Motor

- Control PCB Module

- Induction PCB Module

You can check the Exhaust Fan Motor Shaft to verify your Exhaust Fan Motor Version. The V1 Exhaust Fan Motor has a Round Shaft, while the V2 has a D-Shaft.

The Front Panel displays three values during Fan Calibration:

- Bean Temp: PWM (Pulse Width Modulation) percentage

- Fan Speed: Fan Settings

- Time/Info: Exhaust Fan RPM

Normally, the Exhaust Fan RPM and PWM percentage go up along with the Fan Settings. If the Exhaust Fan RPM remains 0 while the PWM percentage and Fan Settings increase, replace the Exhaust Fan Motor.

Mechanical Troubleshooting

If you hear noises coming out of the Back Assembly when the Bullet is showing A-01, the Exhaust Fan might be having issues spinning properly.

Checking The Back Assembly

The Chaff Filter can rub against the Impeller if it's not properly installed, preventing the Exhaust Fan Motor from spinning.

A loose Impeller or Exhaust Fan Motor can cause wobbling, also rubbing against the Chaff Filter.

Follow the steps below to check the Back Assembly:

- Take off the Chaff Collector.

- Gently lift the Chaff Filter.

- If the Chaff FIlter comes out easily, reseat the Chaff Filter.

- Gently pull the Impeller.

- If the Impeller comes off easily, retighten the Impeller Set Screw.

- Gently rock the Impeller.

- If the Impeller rocks back and forth easily, reinstall the Exhaust Fan Motor.

For the detailed instructions, see the Back Assembly Cleaning Guide and the Exhaust Fan Motor Replacement Guide.

Electrical Troubleshooting

Checking The Connection

If the Exhaust Fan Motor does not spin at all, check the Exhaust Fan Motor connection. If the Exhaust Fan Motor is properly connected, replace the Exhaust Fan Motor.

See the Exhaust Fan Motor Replacement Guide for detailed instructions.

Reviewing Your Ventilation Setup

If the issue persists after the maintenance, review your Ventilation Setup using Venting The R2. Although the document is made for R2, the general principle for the ventilation setup is the same for R1.

Seek Help From Support

If you have done all of the above and the issue persists, contact your reseller or [email protected] (if you have purchased the Bullet directly from Aillio) for further assistance. The rest of the troubleshooting steps can be considered too complicated for a self-help guide.

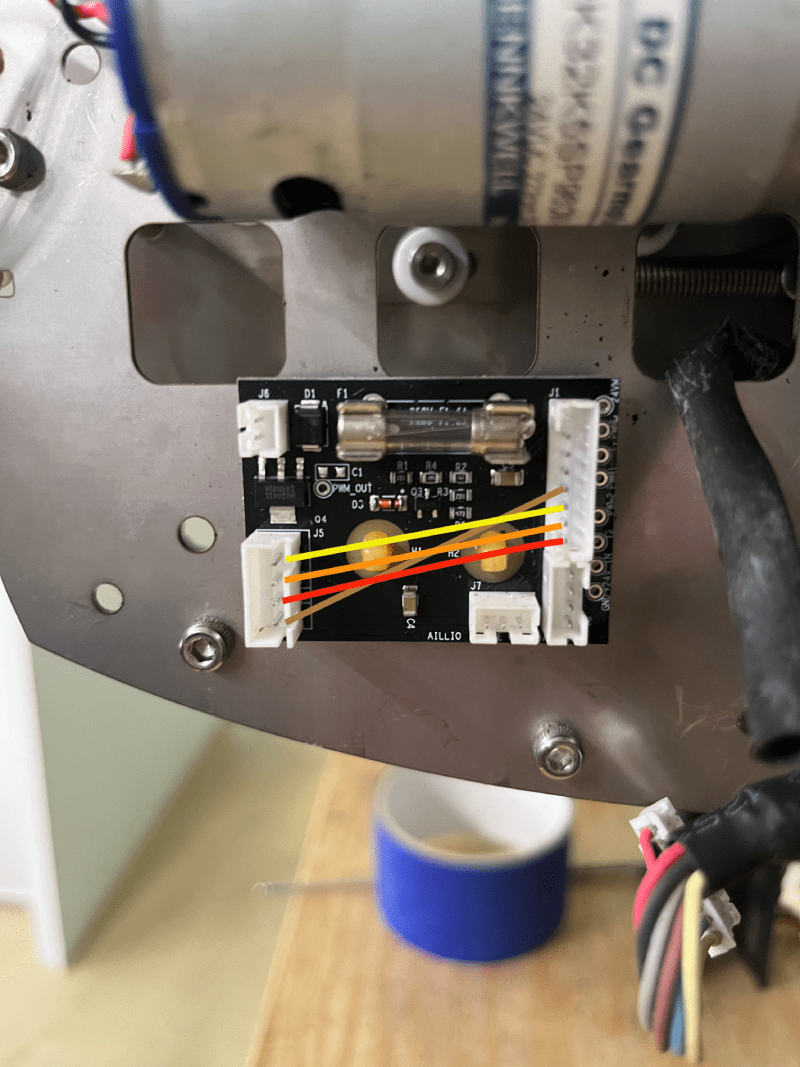

Pros only - Continuity Test and Voltage Output Measurement

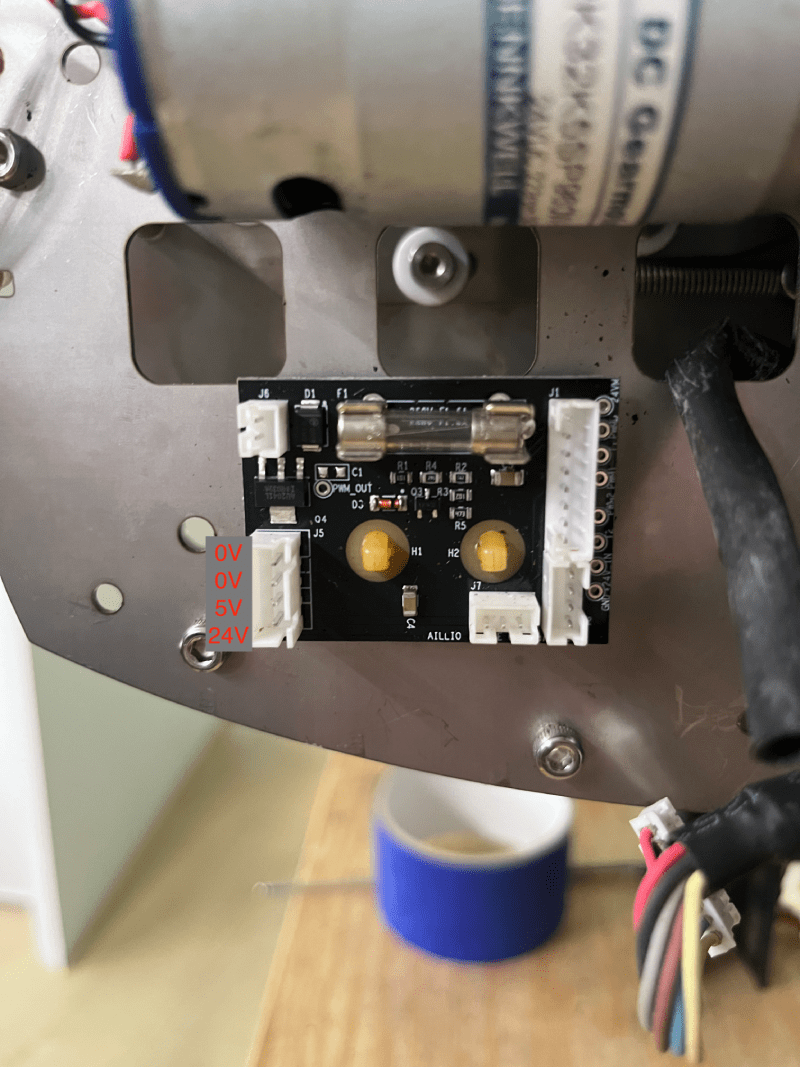

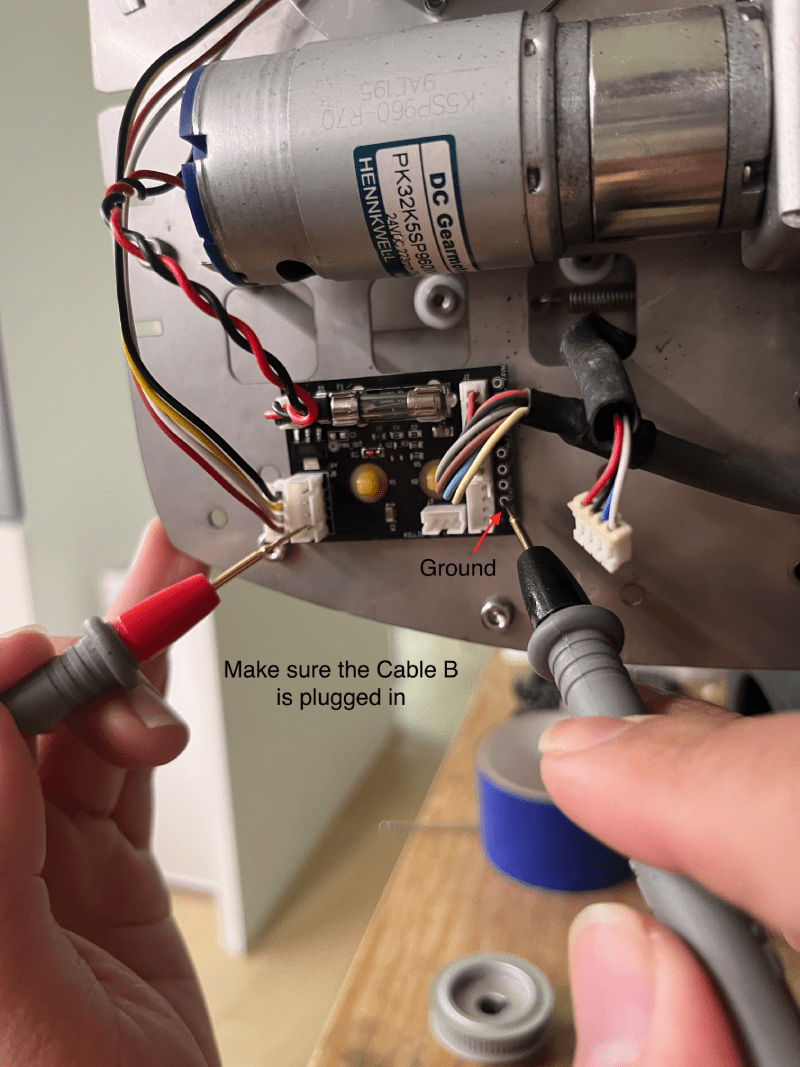

Using a DMM, you can follow this image to test for continuity:

If the Back PCB has passed the continuity test, check their voltage outputs.

If the Back PCB has passed the continuity test but no voltage outputs are present, replace the Induction PCB Module and recalibrate the Exhaust Fan Motor.