ErC 0001

General Knowledge and Inspection

The ErC 0001 (not to be confused with ErC 0000/0001; If the error alternates between 0000 and 0001, please check ErC 0000/0001) shows up when the Bean Temp is above 240°C or the Bean Probe is shorted. To identify the real cause, you can check if the issue shows up right from the startup or only when the Bullet is heated up.

If the ErC 0001 shows up when the Drum is hot (usually during Preheat Mode), the IBTS Lens is dirty and requires maintenance.

If the ErC 0001 shows up during startup or when the Drum is cold, the Bean Probe has a short somewhere and requires a mechanical check.

Maintenance-Related Troubleshooting

You'll most likely see the ErC 0001 showing up when the Bullet is hot. When this happens, we advise checking the IBTS Lens. This is related to how the temperature sensors work inside the Bullet.

The Inner Workings of Temperature Sensors

In a well-maintained Bullet, the IBTS Module looks for the designated IBTS Preheat Temp (100°C - 310°C). Once reached, the Control PCB Module tells the Induction to stop and start heating periodically to maintain the IBTS Temp. While the Bullet tries to maintain the IBTS Temp, the Bean Temp (reading the air inside the Drum) slowly stabilizes.

As the Bean Temp stabilizes, the B-ROR fluctuation gradually decreases, to a point where it's able to stay at 0 for a while. The Bullet then prompts into Charge Mode, ready for the beans to load into the Drum and start roasting.

When the IBTS Lens gets dirty, the IBTS Module reads lower than it should. This means that the Bullet will now preheat to a higher temperature before maintaining it, consequently heating the air inside the Drum to a higher temperature. Since the air inside the Drum is hotter, the Bullet triggers ErC 0001 when the Bean Temp exceeds 240°C.

Although a warmer ambient temp (above 30°C) can cause the Bean Temp to go higher than usual, the ErC 0001 is usually caused by a dirty IBTS Lens.

Identifying a Dirty IBTS Lens

There are many signs indicating that the IBTS Lens is dirty:

- IBTS First Crack Temps are lower than 195°C.

- The Crossovers between the IBTS Temp and Bean Temp are lower than 190°C.

- The roast degree comes out as darker than usual.

If any of above happens, it's usually a good idea to clean the IBTS Lens first before moving to any other troubleshooting steps.

Cleaning and Aligning The IBTS Module

- Clean the IBTS Lens.

- Disassemble the Control Housing and follow the IBTS Installation Guide to check the IBTS Module alignment.

Mechanical Troubleshooting

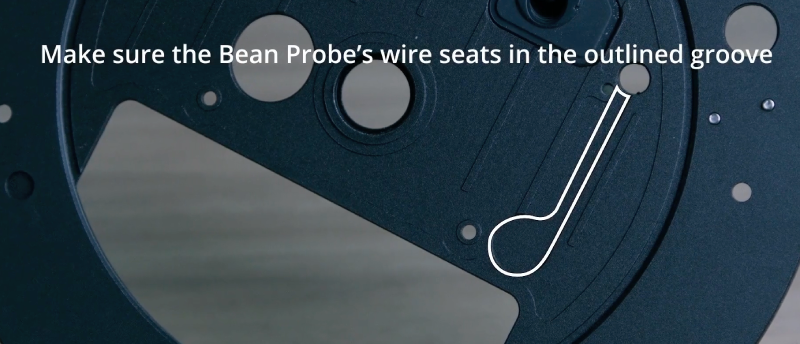

The Bean Probe Wire can be shorted when it's crimped between the Front Plate and Metal Insert (stainless steel panel behind the Front Plate) or between the Front Plate and Control Housing (plastic case at the Front). This typically happens when you have just taken apart the Front Assembly for cleaning.

Checking the Bean Probe

- Follow the Bean Probe Replacement Guide to access the Bean Probe Wire.

- Check if the Bean Probe Connector is damaged.

- Check if the Bean Probe Wire is crimped between the Front Plate and Control Housing.

- Continue the disassembly to check if the Bean Probe Wire is crimped between the Front Plate and Metal Insert.

- Check if the Bean Probe Wire is damaged on the Bean Probe end.

If the issue persists after the Bean Probe is properly installed, the Bean Probe requires a replacement. Contact your reseller or [email protected] to order the part.

Pros only - Continuity and Resistance Test

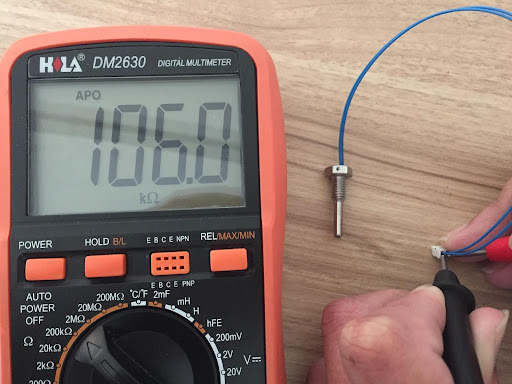

Using a DMM, you can follow this image to test for the Bean Probe's resistance:

The Bean Probe's resistance is 80~90kΩ under room temperature (25°C). The lower the ambient temp, the higher the resistance. If your Bullet is showing ErC 0001, you might see the Bean Probe shorting.